http://www.engineersedge.com/iso_socket_head_screw.htm

Picture below shown Socket Cap Head Screw.

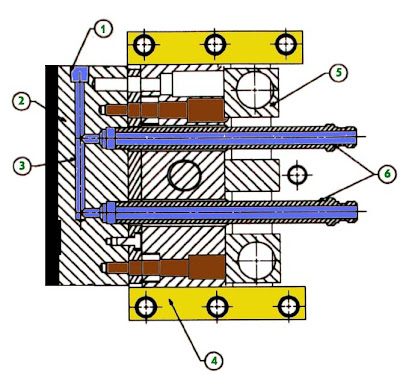

picture below shown cavity main insert and bolts position, i attach the bolts in 4 side symmetrically,

for easy machining process, don't forget this little tips but very important when designing mold, at corner side of pocket make sure you make Radius or half circle, so pocket can be process use in MC easily. i use half circle type in each corner.

Chamfer in Insert

to prevent accident when assembly process, safety reason and easy assembly of mold we need to make little chamfer in each edge of mold, with chamfer it also became guidance when assembly the cavity insert to mold base. see picture below for detail picture, i use C5 in symmetric chamfer and 3-10 in asymmetric chamfer.